|

Why TSI 301 Synthetic Lubricant Works Better

|

|

|

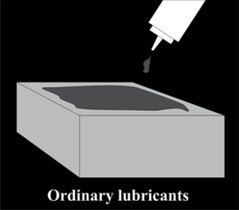

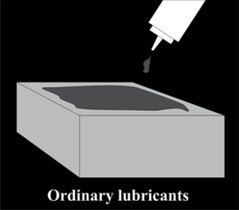

Petroleum-based, silicone, wax, graphite, Teflon, and molybdenum disulphide

lubricants put a relatively thick film on top of a metal surface. The

lubricant rests on top of any corrosion already present, and under pressure

and usage is worn away relatively quickly, requiring constant replenishment. |

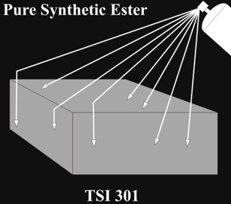

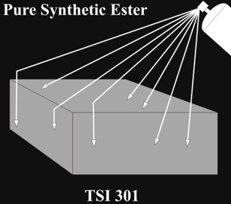

TSI 301 sinks

into the pores of metal. Very little is required. Even when it

appears to be dry it is there. It creates a thin film which tends to

uproot corrosion or contaminants. It bonds itself to the surface of

the metal through physical adsorption reducing surface tension, practically

eliminating friction and reducing wear. It does not build up into

gummy deposits. |

Cleans away rust and contamination better.

TSI 301 contains a mixture of solvents whose

Kauri Butanol Value of 95 (solvency power) makes TSI 301 an extremely effective

solvent. TSI 301 dissolves organic contaminants such as grease and tar,

and loosens frozen or rusted parts by breaking down iron oxide crystals into a

mush which is floated away by TSI 301's higher density.

Superior lubrication efficiency.

TSI 301's super low viscosity means less internal

resistance to rolling or shearing motion. TSI 301's high viscosity index

means that as temperatures climb it will not thin out excessively as other

products do. When temperatures drop it will not solidify easily. As a

result of its friction reducing characteristics it saves energy and transmits

power more efficiently.

Penetrates faster.

TSI 301's low viscosity and low surface tension all it to

cover difficult spaces better and to squeeze rapidly into the smallest spaces.

TSI 301's high Kauri Butanol dissolve and replace iron oxide crystals away.

Does not attract dirt, dust, or lint.

TSI 301 surface characteristics and wear stability

discourage the collection of outside contaminants. TSI 301 bonds to

surfaces by physics adsorption forming a high strength micro thin (less than 1

mil) film. It feels dry to the touch and will not wet or absorb dust

easily. It does not break down into guns with use, making it ideal for

lubricating precision products.

Displaces water better.

TSI 301's higher density (10.2 lbs. gal) and its low

surface and interfacial tensions cause it to flow quickly under moisture.

These water displacement qualities put an end to moisture caused short circuits

improving electrical contact. TSI 301's excellent wetting ability and

tendency to bond with metal gives it an unmatched barrier to moisture.

TSI 301 therefore protects against steam and water corrosion.

Increased wear protection.

TSI 301 increases part life and breaks in new machines and

tools better because of its low viscosity and wide temperature range. Its

low viscosity and shear stability mean less friction. Its propensity not

to collect abrasive contaminant like dirt and dust and not to oxidize or break

down means its better lubrication value is not being eroded by use.

TSI 301 reduces distortion of threads in soft metals. TSI 301 simplifies

the working of hard to work metals. As a result TSI 301 can also mean

enhanced machine output, longer tool life, and greater productivity.

Wider temperature range.

TSI 301's operating range is from -60˚ F to +450˚ F.

In addition because TSI 301's viscosity is so stable over this range it is more

efficient than other lubricants saving equipment subjected to unexpected

extremes. Unlike oils its structure does not break down or oxidize under

extended high temperature operation.

Reduced residue (varnish, gum, sludge, carbon)

TSI 301 is a synthetic organic ester. It is not a

petroleum based oil. It does not contain suspended particles (such as Teflon,

graphite, molybdenum), nor is it a polyglycol. It's residue is less than

.196. It does not build up, form gummy deposits or break down into sticky

tars and abrasive carbons. TSI 301 does not oxidize as a result of

temperature or air contact, so it does not form corrosive organic acids as it is

being used. As a result TSI 301 continues to lubricate long after others

have stopped working.

Better rust & corrosion protection.

TSI 301 seals metal away from corrosion. Its low

surface tension allows it to form a film which covers even complex surfaces

completely. TSI 301's low permeability keeps air and water from

penetrating. With use more products oxidize lowering their surface

resistance to water and air permeation. TSI 301 does not oxidize with use

so its protection lasts long after others have failed. TSI 301 needs only

one coat to work.

Less flash and fire hazard.

TSI 301 unlike most products will not burn. It has

no flash point. It is safe to use near fires or on hot metals.

With reduced fire hazards insurance premiums can often be lowered.

Reduced lubricant consumption.

TSI 301 needs to be replaced much less frequently then

other products. It does not burn off like solid lubricants nor does it

oxidize like petroleum based products. It has a low vapor pressure at even

elevated temperatures and tends to cling to the metal surfaces by physics

adsorption. Less TSI 301 is used and considerable savings can be realized.

Withstands extreme pressure.

TSI 301's physical bonding to the surface of metals

(adsorption) and its high film strength allows it to form a lubrication boundary

as small as (10-7 inches) thick. TSI 301 operates where surface type

lubricants would break down or be squeezed out.

Superior high speed performance.

TSI 301 maintains its laminar flow characteristics at

speeds of even 10,000 RPM's. Operating temperature and friction causing

turbulence is reduced because of it's low viscosity.

|

|

|

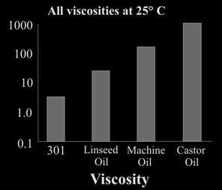

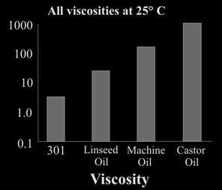

Viscosity is the resistance of a

liquid to flow. The viscosity of a lubricant can affect friction loss,

load carrying capacity, heat generation and film thickness. TSI 301's

low viscosity means lower internal friction loss. |

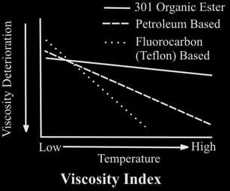

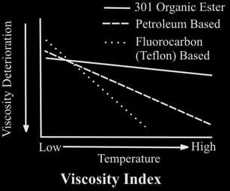

The viscosity index is a measure of

the relationship between viscosity and temperature. The higher the

index the more stable the viscosity is over a wide temperature range.

TSI 301's high index provides better wear protection at high and low

operating temperatures. |

Does not conduct electricity (anti-static).

TSI 301 has an unusually high dialetic constant giving it

many unique electrical properties. Voltages as high as 41,000 volts and

long term nuclear radiation (10-11 rads) do not break down TSI 301.

It is ideal for electronic equipment because it is a non-conductor. It

does not collect static electricity or affect electrical properties. It

has proven effective to prevent tuner drift. It reduces arcing.

TSI 301 reduces galvanic corrosion between dissimilar metals.

Will not stain.

TSI 301 is a greaseless synthetic compound, it is not oil

based or a suspension of solids. Its solvent base is often used for

cleaning components. Unlike other products it does not tend to collect

dirt and grime. TSI 301 does not stain fabrics.

Prevents seizure.

TSI 301 prevents high speed seizure by being an extremely

good conductor of heat away from critical surfaces. Because of its

superior viscosity characteristics it also lubricates better, resulting in less

heat being generated. TSI 301's ability to bond to metal surfaces makes it

extremely protective even after years of use. As a result it is a superior

anti-seize compound.

Better results with high performance metals.

TSI 301 has a low sulfur and halogen residue. It

does not contain heavy metals such as lead or mercury. It will not cause

stress corrosion, cracking, or hydrogen embrittlement of such metals as

stainless steel, magnesium, or titanium.

Preserves wood & leather.

TSI 301 is an effective preservative of wood

and leather surfaces. Its tendency to bond with the surface and its low

viscosity cause it to cover the surface. It is very effective on leather

hinges and wood exposed to the elements.

Easier disposal.

TSI 301 is more biodegradable than petroleum based

lubricants making it less expensive and easier to dispose of.

Convenient to use.

TSI 301 comes in a variety of ready to use aerosol and

bulk containers to meet every need. Its many applications make it a

replacement for the many limited use lubricants on the market.

buy |

back

©2025 american gas & chemical co. ltd., Northvale, NJ

|